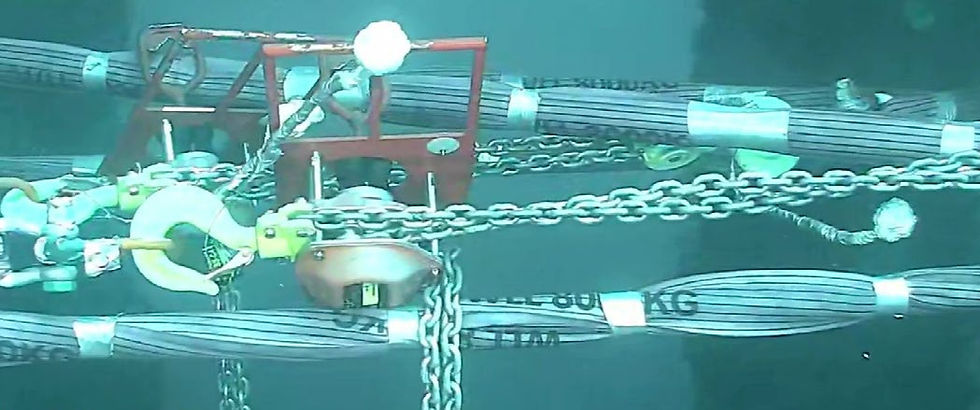

William Hackett Remote Operated Vehicle (ROV) Chain Hoists

- Robert Robinson

- Aug 16, 2021

- 2 min read

William Hackett Lifting Products (WHLP) continually challenge themselves to innovate, design and manufacture safer lifting products across multiple sectors.

Over the last 40 years the lifting industry has seen an increase in the demand for hoisting which is suitable for challenging subsea environments. Offshore lifting operations incorporating hoists assume a level of safety based upon the resilience of the hoist’s mechanical failure. Although mechanical failures in modern hoists are rare, years of experience accumulated within WHLP identified a fundamental mechanical design that would eliminate one potential mode of failure.

Resilience to Failure

William Hackett therefore designed, patented, and manufactured the ‘Quad Pawl’ (QP). This technology was originally incorporated in their subsea L5 Lever Hoist and was the first in the world to provide four pawl mechanical engagement. This advanced technology is now available within their range of ROV Subsea Chain Hoists. How does it work? Essentially as the number of pawls increase so does the resilience to failure, which enhances the capabilities of the hoist allowing all four pawls to engage with the ratchet gear in an offset configuration allowing finer adjustment and tensioning capability while maintaining pawl/ratchet gear engagement.

Bespoke Capabilities

William Hackett have worked closely with industry stakeholders to further develop and enhance the capa bility of the ROV SS-C4 chain hoist giving users a number of ROV drive interface options to choose from including D-Link, Fishtail, Hydraulic Hot Stab and Torque Bucket. Through continued dialogue with customers, and extensive experience in the ROV offshore market they have developed the ability to attach bespoke top and bottom terminal fittings such as ROV compatible sling hooks, shank hooks and shackles. This adaption allows the operator to access the top and bottom connection fittings of the chain hoist and other components of the rigging assembly easily and safely.

Corrosion Protection

An important question to ask subsea hoist suppliers and manufacturers is, what are the corrosion protection properties of the hoist? The WH ROV Chain Hoist benefits from:

AkzoNobel Interpon D1010 high durability powder coating which is resistance to colour change and ensures long-term corrosion protection;

Neutral salt spray test to ISO 9227resisting against corrosion for 1500 hours;

Hyperbaric tested at 3000 metre water depths;

All fixings and fasteners made from stainless steel.

Testing

As part of the company’s continual commitment of investment, a new state of the art 75t hydraulic vertical test bed has been built and commissioned at their manufacturing facility in Alnwick, UK. This allows verification testing to be carried out on both the hydraulic system of the hoist as well as the mechanical properties, under specific test loads in both upward (lifting) and downward (lowering) directions.

Comments