Assuring Foundation Integrity: Why Accurate Grout Monitoring Matters More Than Ever

- Robert Robinson

- 3 days ago

- 2 min read

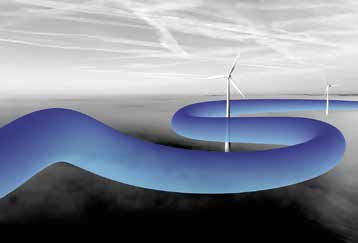

As offshore wind projects scale up in size and move into deeper, more challenging waters, the expectations placed on subsea construction quality have never been higher. Foundation installation is one of the most critical stages in an offshore wind farm’s lifecycle, and grout, the material securing monopiles and jackets to their transition pieces, plays a central role. Ensuring its density and consistency in real-time is essential for long-term structural integrity.

However, verifying grout quality offshore remains a significant technical challenge. Installation teams often work within tight weather windows, low visibility, variable sea temperatures and high hydrodynamic forces. Under these conditions, traditional grout assurance methods, such as intermittent sampling or visual observation topside, can introduce uncertainty. Density may drift outside of the specification without immediate detection, risking weak bonding, poor load transfer, or early fatigue issues in the structure.

Tracerco Diagnostics™ Grout Monitoring technology addresses this challenge by giving operators a clear, real-time view of grout quality as it is pumped subsea. Using proven measurement principles, grout density monitoring (GDM) verifies density continuously, allowing installation teams to confirm that the grout entering the structure meets the exact design criteria required for performance and durability. The technology acts as a direct assurance layer at a point in the workflow where corrective action is still possible.

“Offshore wind developers face increasing technical and commercial pressure to get foundation installation right the first time,” says Donald Ballantyne, Subsea Business Development Manager at Tracerco. “Grout quality determines how well loads are transferred between structural components. If density falls below specification, developers risk long-term integrity problems. GDM provides operators with the certainty they need to maintain quality, avoid rework, and reduce both cost and carbon footprint.”

Density is the key parameter because it directly relates to compressive strength, curing behaviour and the overall bonding performance of the grout. Without accurate, continuous measurement, small deviations can go unnoticed until installation is complete, which reduces confidence in structural performance.

By delivering immediate measurement, GDM helps prevent both underperformance and unnecessary over-pouring. Historically, operators have used excess grout as a buffer against uncertainty, increasing material usage, vessel time, and environmental impact. Real-time monitoring allows for more precise pumping, improved material efficiency and reduced waste - a growing priority as the industry moves toward more sustainable construction practices.

Beyond installation, GDM also supports quality documentation and certification. As offshore wind supply chains become more complex and regulatory expectations tighten, operators increasingly require verifiable measurement records for each stage of construction. GDM provides clear, traceable data that supports quality assurance frameworks and long-term asset management.

Importantly, GDM is already proving its value globally. Tracerco recently completed its first offshore wind GDM project in Taiwan, where the system helped confirm “right first time” foundation installation for a major development - reducing uncertainty and enhancing construction efficiency in a region experiencing rapid offshore wind growth.

While grout may be a small part of a vast engineering process, its impact on offshore foundation performance is substantial. The Tracerco Diagnostics™ Grout Monitoring technology provides real-time clarity and measurable assurance, developers can mitigate risk and reduce uncertainty.

+44 (0) 1642 375500

Comments